Exploring the Types of Printing: Digital vs. Offset

Share

In the realm of printing, two prominent technologies have emerged as key players: digital printing and offset printing. Each method comes with its own set of advantages and considerations, catering to distinct printing needs. This article aims to delve into the intricacies of digital and offset printing, providing a comprehensive understanding of the differences between these two widely used printing technologies.

1. Precision and Setup: Digital Printing Takes the Lead

One of the defining characteristics of digital printing is its precision and minimal setup requirements. Unlike offset printing, which relies on printing plates and extensive setup, digital printing allows for on-the-fly customization and quick turnarounds. This makes it an ideal choice for short print runs, variable data printing, and projects that demand swift production without compromising quality.

2. Cost-Effectiveness: The Offset Advantage for Large Runs

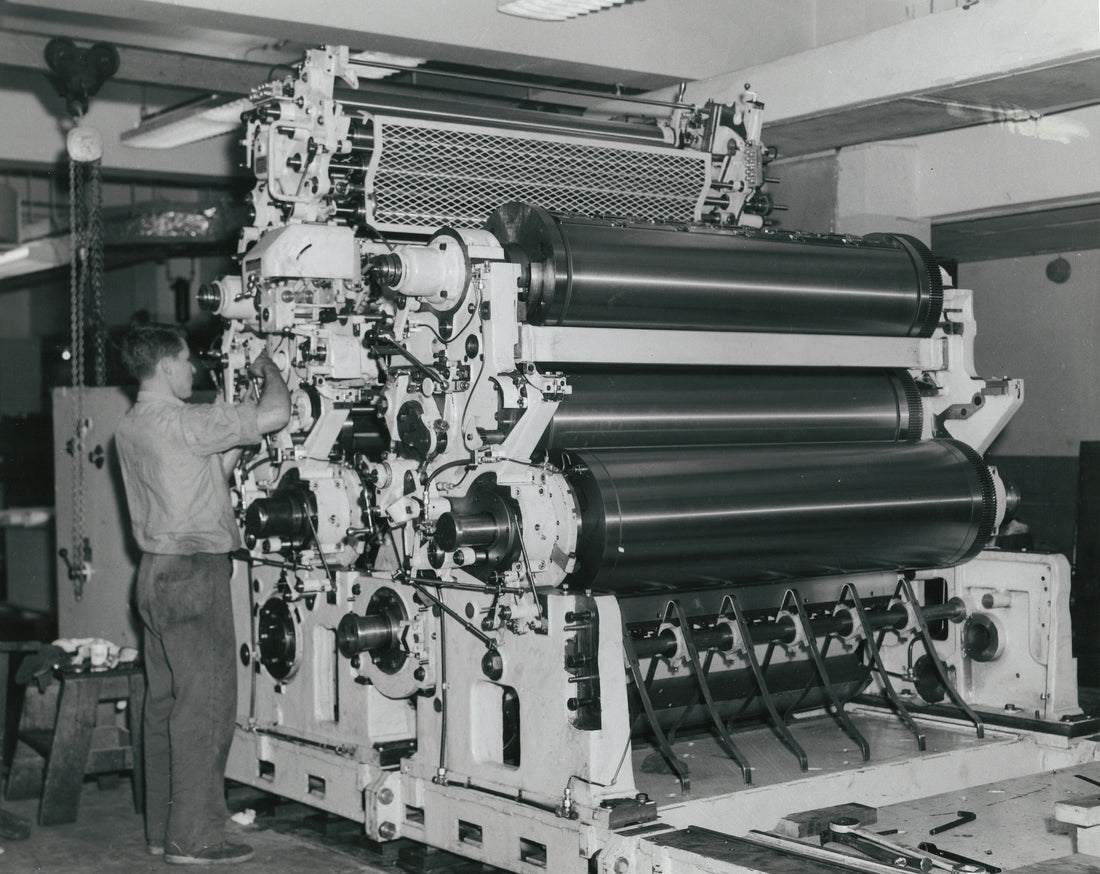

When it comes to high-volume printing, offset printing has long been the go-to choice for its cost-effectiveness. While the initial setup costs can be higher due to the creation of printing plates, the per-unit cost decreases significantly with larger print runs. Offset printing is economically advantageous for large-scale projects such as magazines, newspapers, and brochures, where the savings on each unit become substantial.

3. Color Accuracy and Consistency: A Stalemate?

Both digital and offset printing have made significant strides in achieving exceptional color accuracy and consistency. Digital printing has improved its color matching capabilities, often rivaling offset in this aspect. However, offset printing, with its precise Pantone color matching system, is still regarded as the gold standard for achieving consistent and accurate colors, making it the preferred choice for projects with stringent color requirements.

4. Versatility in Substrates: A Win for Digital Printing

Digital printing scores a victory in terms of substrate versatility. It can effectively print on various materials, including paper, cardboard, fabric, and even certain plastics, without the need for additional treatments. This flexibility makes digital printing an excellent choice for projects that involve unconventional or specialty substrates. On the other hand, offset printing may face limitations in printing on certain materials without additional processes.

5. Customization and Variable Data: Digital Printing's Forte

In the era of personalized marketing, digital printing stands out for its ability to handle variable data effortlessly. This means that each printed piece can be customized with unique text, images, or other elements without slowing down the printing process. For applications like direct mail campaigns, personalized promotional materials, or customized packaging, digital printing provides a level of flexibility and personalization that offset printing struggles to match.

Conclusion: Choosing the Right Technology for Your Project

In the digital vs. offset printing debate, there is no one-size-fits-all answer. The choice between these technologies depends on the specific requirements of your project, including print volume, color accuracy, substrate type, and customization needs. By understanding the strengths and limitations of digital and offset printing, you can make informed decisions that align with your goals, ensuring that your printed materials achieve the desired impact in the competitive world of visual communication.

1. Precision and Setup: Digital Printing Takes the Lead

One of the defining characteristics of digital printing is its precision and minimal setup requirements. Unlike offset printing, which relies on printing plates and extensive setup, digital printing allows for on-the-fly customization and quick turnarounds. This makes it an ideal choice for short print runs, variable data printing, and projects that demand swift production without compromising quality.

2. Cost-Effectiveness: The Offset Advantage for Large Runs

When it comes to high-volume printing, offset printing has long been the go-to choice for its cost-effectiveness. While the initial setup costs can be higher due to the creation of printing plates, the per-unit cost decreases significantly with larger print runs. Offset printing is economically advantageous for large-scale projects such as magazines, newspapers, and brochures, where the savings on each unit become substantial.

3. Color Accuracy and Consistency: A Stalemate?

Both digital and offset printing have made significant strides in achieving exceptional color accuracy and consistency. Digital printing has improved its color matching capabilities, often rivaling offset in this aspect. However, offset printing, with its precise Pantone color matching system, is still regarded as the gold standard for achieving consistent and accurate colors, making it the preferred choice for projects with stringent color requirements.

4. Versatility in Substrates: A Win for Digital Printing

Digital printing scores a victory in terms of substrate versatility. It can effectively print on various materials, including paper, cardboard, fabric, and even certain plastics, without the need for additional treatments. This flexibility makes digital printing an excellent choice for projects that involve unconventional or specialty substrates. On the other hand, offset printing may face limitations in printing on certain materials without additional processes.

5. Customization and Variable Data: Digital Printing's Forte

In the era of personalized marketing, digital printing stands out for its ability to handle variable data effortlessly. This means that each printed piece can be customized with unique text, images, or other elements without slowing down the printing process. For applications like direct mail campaigns, personalized promotional materials, or customized packaging, digital printing provides a level of flexibility and personalization that offset printing struggles to match.

Conclusion: Choosing the Right Technology for Your Project

In the digital vs. offset printing debate, there is no one-size-fits-all answer. The choice between these technologies depends on the specific requirements of your project, including print volume, color accuracy, substrate type, and customization needs. By understanding the strengths and limitations of digital and offset printing, you can make informed decisions that align with your goals, ensuring that your printed materials achieve the desired impact in the competitive world of visual communication.